Production techniques and systems

Using computer aided design (CAD) and computer aided manufacture (CAM) in a manufacturing setting

Developments in mass productionWhen the same product is manufactured many times. techniques have led to a variety of production methods being created to improve efficiency by saving time and cutting costs.

Automation

The automationUsing automatic equipment in production. of workplaces has led to an increase in skilled workers but a decrease in job opportunities, as machines have taken over the jobs previously done by humans. Automation has streamlined the manufacturing system by increasing production and reducing errors.

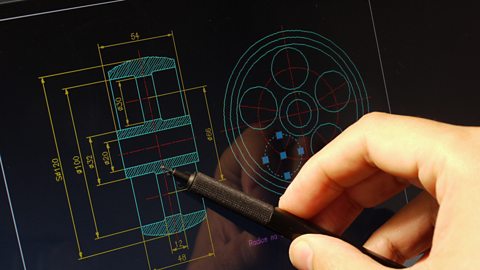

Computer aided design (CAD)

computer aided design (CAD)The process of creating a 2D or 3D design using computer software. now has the capability to design new products in 3D, visualise them in a variety of materials and send images around the world for collaboration and consultation. Once production is finalised, these designs are sent to computer aided manufacture (CAM) machines to be formed. Autodesk and Solidworks are common forms of CAD software used.

| Advantages of CAD | Disadvantages of CAD |

| Ideas can be drawn and developed quickly | Expensive to set up |

| Designs can be viewed from all angles and with a range of materials | Needs a skilled workforce |

| Some testing and consumer feedback can be done before costly production takes place | Difficult to keep up with constantly changing and improving technology |

| Advantages of CAD | Ideas can be drawn and developed quickly |

|---|---|

| Disadvantages of CAD | Expensive to set up |

| Advantages of CAD | Designs can be viewed from all angles and with a range of materials |

|---|---|

| Disadvantages of CAD | Needs a skilled workforce |

| Advantages of CAD | Some testing and consumer feedback can be done before costly production takes place |

|---|---|

| Disadvantages of CAD | Difficult to keep up with constantly changing and improving technology |

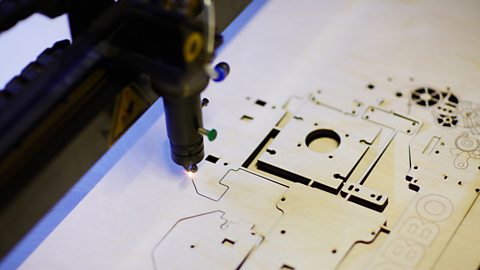

Computer aided manufacture (CAM)

By using computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer., designs can be sent to CAM machines such as laser cutters, 3D printers and milling machines.

| Advantages of CAM | Disadvantages of CAM |

| Fast and accurate production | Expensive to set up |

| Machines can run constantly on repetitive tasks | Needs a skilled workforce of engineers |

| Advantages of CAM | Fast and accurate production |

|---|---|

| Disadvantages of CAM | Expensive to set up |

| Advantages of CAM | Machines can run constantly on repetitive tasks |

|---|---|

| Disadvantages of CAM | Needs a skilled workforce of engineers |

Flexible manufacturing systems (FMS)

flexible manufacturing system (FMS)A manufacturing process that can be modified at different points to produce different quantities or different parts for a product. are a series of different machines producing different parts for a product. The system is flexible because, at any time, machines in the process can be reprogrammedTo program a computer again with different information. to change their task and production can be changed to produce more or fewer parts without stopping the other areas of the process.

Just in time (JIT)

just in time (JIT) manufacturingMaterials or parts are delivered just before they are needed. is triggered by a customer order. The correct amounts of materials are ordered in to cover the order, and these arrive just as they are needed by production. This saves money on storage, reduces waste and ensures there is no money wasted producing stock that will remain unsold. There are disadvantages to the system in that, if any part of the product cannot be sourced, clientIn business, a client is a person or organisation that wants a product manufactured, eg a retailer. have to wait for their order to be produced.

Lean manufacturing

lean manufacturingA systematic approach to minimising waste within a manufacturing system. is a Japanese concept, based on minimising costs and maximising efficiency by cutting down on waste and the amount of materials and energy used in production. This is done by adapting designs and making changes to the production process. For example, to reduce waste, a packaging net could be redesigned to include a tessellatingShapes that fit together repetitively. pattern or, to improve efficiency, changeover times between production runs could be reduced.