Core technical principles

Considering usability when designing - OCR

Designers should consider usability when designing so their products are inclusive, easy to use and do not cause discomfort, pain or even injury. This is made easier by advancements in technology.

New and emerging technologies - OCR

Companies are trying to save money, improve products, develop new materials and become more efficient. New technologies are developed to positively impact the manufacturing industry and society.

Energy generation and storage - OCR

Energy generation and storage have a huge global impact on our lives - from decisions about the use of fossil fuels and their effect on our environment, to the development of cleaner, more modern ways to create and store energy.

Developments in new materials - OCR

Developments in science and engineering lead to changes in materials technology. There are a range of modern materials with impressive properties, as well as traditional ones such as wood or metal.

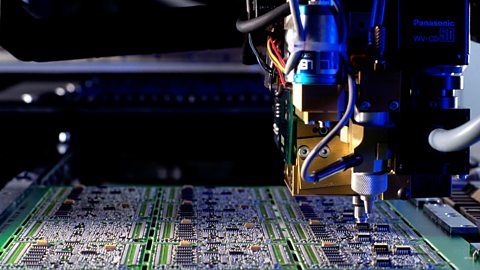

Electronic systems - OCR

The systems approach to designing with programmable electronic devices is vital in understanding how today’s electronic devices are programmed together with how they operate in the real world.

Mechanical devices - OCR

Mechanical devices can change one form of force to another. All moving parts work on some sort of mechanism.

Material categories and properties - OCR

All materials have physical and working properties. Physical properties are the traits a material has before it is used, whereas working properties are how the material behaves when it is manipulated.

In-depth technical principles

Papers and boards - OCR

Paper is made from wood pulp or recycled material. It may be used in packaging, drawing and sketching, or model making.

Timbers - OCR

Hardwood and softwood are types of timber that come from many different trees. Manufactured boards such as MDF and plywood are man-made.

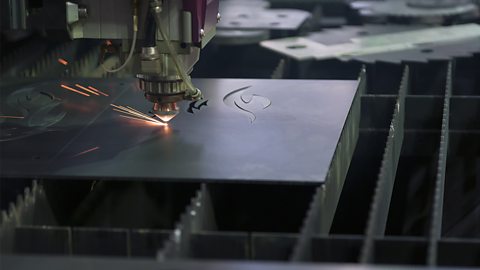

Metals - OCR

Metals come from an ore that is mined from the ground. Metals can be used for all methods of production, from bespoke pieces of jewellery to mass-produced cars.

Polymers - OCR

Most polymers are manufactured and are designed by chemical engineers. Most are made using non-renewable crude oil. Difficulties around disposal mean there is a drive to reduce the use of plastics.

Fibres and fabrics - OCR

Textiles are made from fibres, classified as either natural or manufactured. Fibres are twisted into yarns before being made into woven, knitted or bonded fabrics.

Design engineering - OCR

Design engineering is the study of problem solving by ‘traditional’ engineering and design. It applies an understanding of materials, creative design thinking and manufacturing techniques.

Designing and making principles

Investigating - OCR

During the designing and making processes it is important to gather feedback from the client and users. Refining the product based on this feedback helps solve any problems before production begins.

Designing - OCR

Designers use many techniques to create products and solve problems. Design and development involve creating working drawings and parts lists to enable a third party to manufacture the design.

Making - OCR

Manufacturers need to consider the form, function and cost of designs before production. Designers need to consider safety, availability of materials and minimising waste, while maintaining quality.

Evaluating - OCR

Evaluating ideas, models and feedback is an ongoing process, utilised in continuing to adapt and improve products to make them more useful, appealing and profitable.

Links

- External linkExternal link

- External linkExternal link

- External linkExternal link

- External linkExternal link

- External linkExternal link

- SubscriptionSubscription